Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

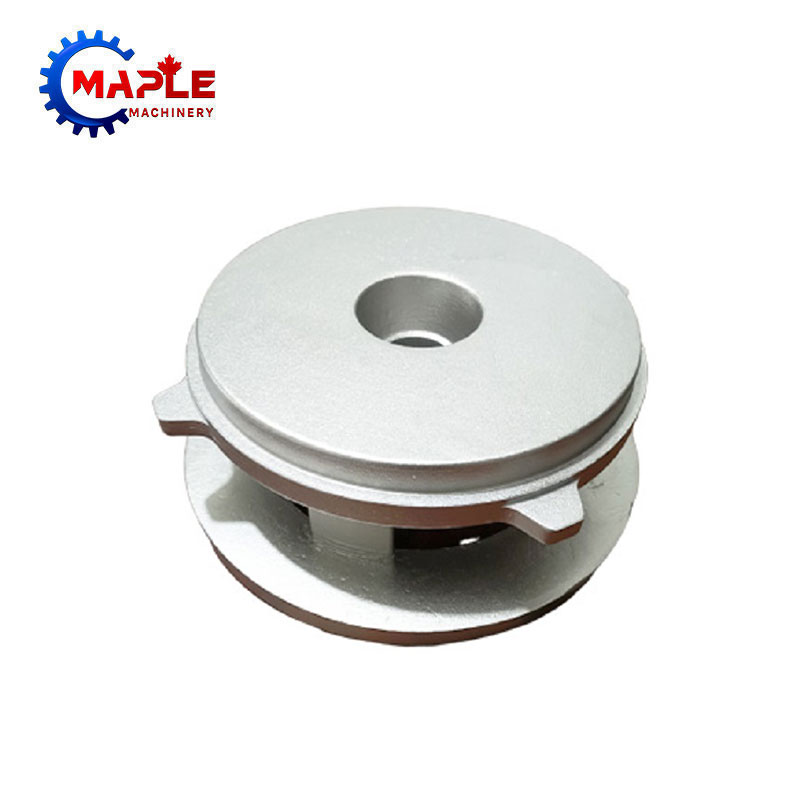

Deli iz nodularnega litega železa Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

Deli za ulivanje iz izgubljenega voska za gradbene stroje

Vsi deli strojev Maple za jeklene litine iz izgubljenega voska za gradbene stroje so izdelani z notranjo trdnostjo in celovitostjo. S prefinjenim postopkom Lost Wax Casting lahko izdelamo dele s strogimi tolerancami. Stroji Maple uporabljajo programsko opremo za modeliranje strjevanja za napovedovanje notranje ravni kakovosti ulitkov, preden so deli izdelani, kar močno skrajša čas do trga in stroške razvoja s pristopom "poskusov in napak" pri razvoju procesa.Deli za natančno litje jekla v gradbeništvu

Maple machinery je proizvajalec delov za natančno litje jekla za različne industrijske potrebe. Ponosni smo na dodajanje vrednosti vašim delom za natančno litje jekla. Deli za precizno litje jekla za gradbeništvo so eden izmed naših številnih izdelkov. Imamo izkušnje s proizvodnjo delov za precizno litje jekla za gradbeništvo. Zaupanje izhaja iz naših več kot 15 let izkušenj v proizvodnji.Deli za litje iz nerjavečega jekla za predelavo hrane

Strojni inženirji podjetja Maple za Food Process Machine delujejo kot razširitev vaše organizacije pri razvoju preciznega litja. Z vedno premislekom, ali bi lahko bile stvari »tehnično boljše, drugačne, cenejše in/ali enostavnejše«, dobimo najboljšo rešitev po konkurenčni ceni. Z veseljem delimo svoje znanje o tehnikah litja z vami, da oblikujemo najboljše dele za litje iz nerjavečega jekla za stroje za predelavo hrane.Jekleni kovaški deli za kmetijske stroje

Maple Machinery Co., Ltd., ki se nahaja v Ningboju na Kitajskem, je že več kot 20 let profesionalni proizvajalec zaprtih odkovkov, specializiran za zagotavljanje visokokakovostnih jeklenih delov za kovanje kmetijskih strojev. Poleg tega lahko nudimo tudi druge storitve z dodano vrednostjo za končne izdelke. Zato, če potrebujete kovanje in strojno obdelane dele, nas kontaktirajte!Zaprti kovani deli jekla za težko industrijo

Stroji Maple so specializirani za zaprto kovanje, proizvodnjo visokokakovostnih jeklenih delov za zaprto kovanje v težki industriji. Naše področje poslovanja je globalno trženje. Trenutno je podjetje vzpostavilo dolgoročne odnose sodelovanja s številnimi znanimi strankami doma in v tujini. Kultura strojev Maple je ustvarjanje vrednosti za lastno izkoriščanje. Njeni največji upravičenci so stranke. Kot rezultat, so Maple machinery bili in bodo še naprej zanesljiv in predan partner našim strankam.Odkovki iz nerjavečega jekla za pomorstvo

Maple machinery želi preseči pričakovanja strank v vseh pogledih. Naša ekipa ima pri tem pomembno vlogo. Izpolnite pričakovanja kupcev za proizvodnjo delov za kovanje iz nerjavečega jekla za pomorstvo. Želimo, da so naše stranke zadovoljne skozi celoten proces in ostanejo popolnoma zadovoljne z našimi storitvami in izdelki. Navsezadnje so zadovoljne stranke last prihodnjih naročil.

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy