Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

Oprema za predelavo hrane jekleni vložni ulitki Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

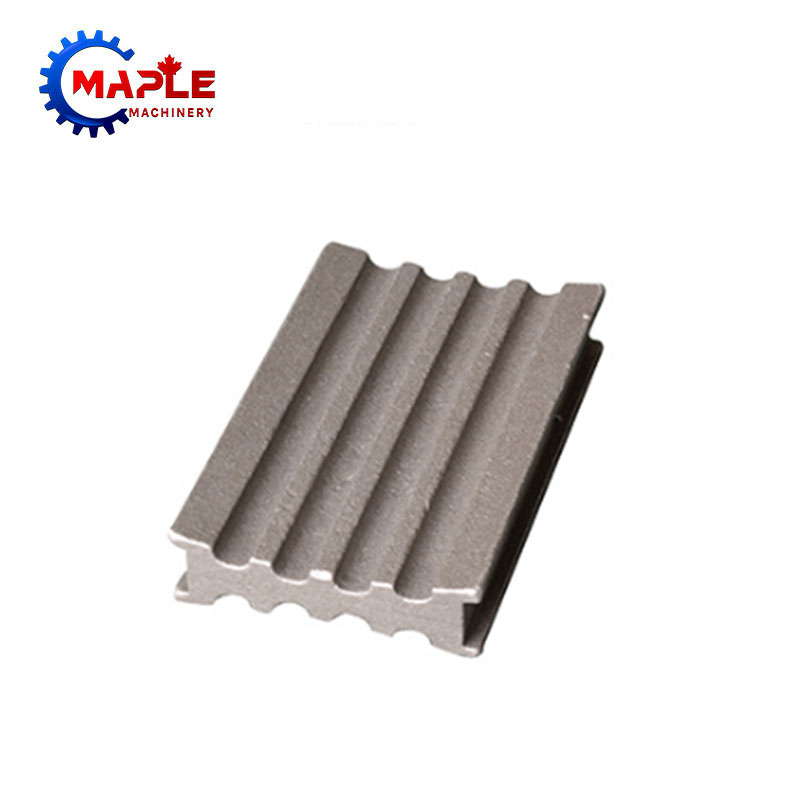

Industrija recikliranja Deli za litje železa v pesek

Maple machinery je livarna visokokakovostnih ulitkov iz sive in nodularne litine za industrijo recikliranja. Podjetje je v ospredju svojih ciljev maksimiranja zadovoljstva strank in visoke kakovosti ter zagotavljanja visokokakovostnega peska za dele za litje železa v pesek za reciklažno industrijo za zagotavljanje bistvenih podpornih storitev, kot so proizvodnja kalupov in storitve skladiščenja, testiranje in vrednotenje kovin, izdelava prototipov, deli dodelava, predelava, premazovanje in toplotna obdelava.Deli za natančno litje jekla v težki industriji

Stroji Maple imajo najbolj zanesljive izdelke in storitve. Prav tako lahko dosežemo najbolj dosledno dobavo in varnost najboljše kakovosti zaradi naše odlične vertikalne integracije – zmožnosti zagotavljanja celovite storitvene rešitve od rudarjenja do proizvodnje. Zato so deli za natančno litje jekla v težki industriji za stroje Maple vsekakor najboljši, kar je mogoče.Deli za natančno litje morskega jekla

Maple Machinery ima profesionalno opremo za litje in bogate izkušnje z deli za natančno litje morskega jekla. In odlična lokacija v bližini pristanišča. Imamo svoj edinstven način izdelave jeklenih ulitkov za ladje. Pomagajte strankam prihraniti stroške in skrajšati čas proizvodnje. Izboljšajte kakovost proizvodnje.Deli za jeklene litine v gradbeništvu

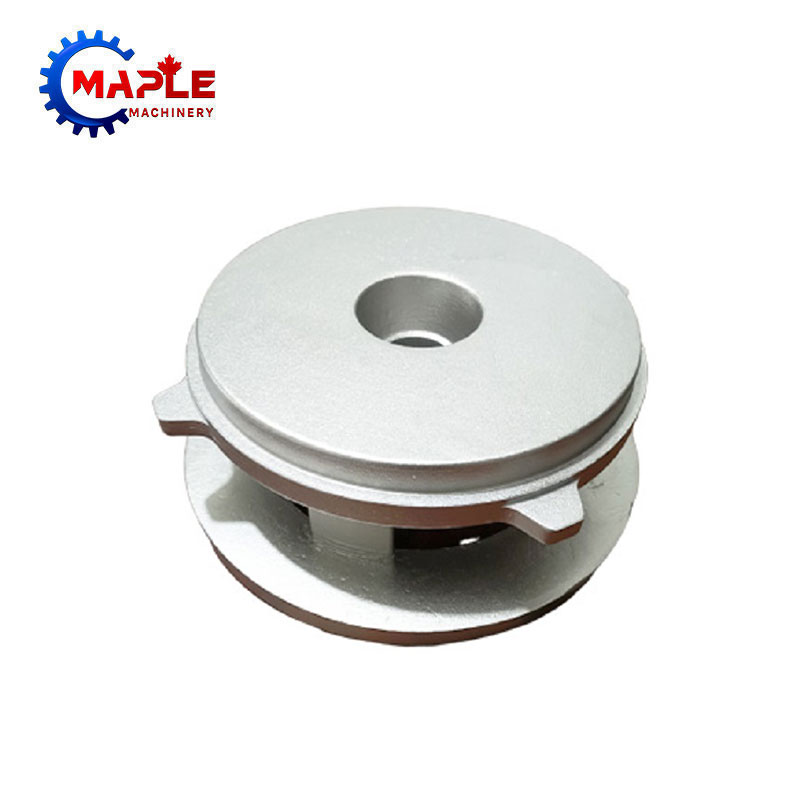

Maple machinery ima več kot 15 let izkušenj v jeklarski industriji, zato imamo veliko izkušenj tudi s proizvodnjo delov za jeklene litine v gradbeništvu in imamo svoje edinstvene vpoglede. Vemo, kaj je za vas najpomembnejše: poleg kakovosti, garancije dostave in cene je rešitev na prvem mestu. Konstrukcijsko znanje, izbira aplikacij, poznavanje tehnologije materialov in izbira proizvodne tehnologije so samoumevni.Deli za jeklene litine strojev za predelavo hrane

Certificiran sistem vodenja kakovosti Maple machinery zagotavlja, da so organizacijski in načrtovalni procesi optimizirani v našem vsakodnevnem poslovanju. Posledično lahko nenehno izboljšujemo naše notranje procese in izdelke. Za zagotovitev, da so vsi deli za jeklene litine strojev za predelavo hrane v skladu s standardom. Stroji Maple so služili strankam v industriji strojev za predelavo hrane. Doseženi so tudi dobri dosežki.Odkovki jeklenih delov za mornarje

Kovanje jekla je glavna vrsta kovinskega kovanja tehnologija oblikovanja jekla, ki uporablja lokalno stiskalno silo. Odkovki so bili podvrženi pomembnim spremembam, kar je privedlo do učinkovitejših, hitrejših in dolgotrajnejših procesov. Dandanes se ladijski jekleni kovani deli običajno izdelujejo z električnimi, hidravličnimi ali kovaškimi stiskalnicami ali udarnimi orodji na stisnjen zrak. Vroče kovanje vključuje segrevanje obdelovanca na približno 75 % temperature taljenja.

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy