Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

Odlitki iz železnega peska za komponente ventilov Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

Jekleni kovaški deli hidravličnega sistema

Maple Machinery je popolna in popolnoma integrirana oprema za kovanje in obdelavo, specializirana za proizvodne projekte po meri. Hidravlični sistem iz ogljikovega, legiranega in nerjavnega jekla Jekleni kovaški deli, teža 0,1 kg-60 kg. Javor lahko zmanjša zamudo pri toplotni obdelavi, kovanju in dostavi ter izboljša kakovost.Kovani deli iz nerjavečega jekla v gradbeništvu

Pomen nosilcev iz nerjavečega jekla v širokem svetu gradbeništva, inženiringa, gradbenega in konstrukcijskega jekla. Kovani nosilci iz nerjavečega jekla so že več kot 15 let pomemben del gradbeništva. Kot dobavitelj delov iz nerjavečega jekla Maple machinery proizvaja različne dele za kovanje iz nerjavečega jekla v gradbeništvu, ki jih je za vas prilagodila naša ekipa. Smo zaupanja vreden proizvajalec vaših delovDeli za litje železa v pesek za predelavo hrane

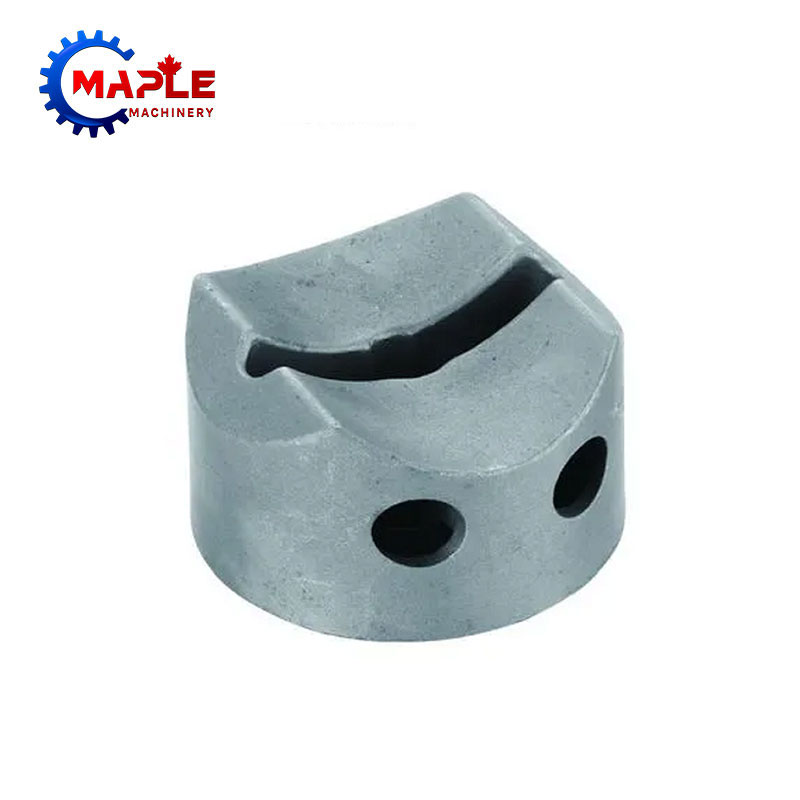

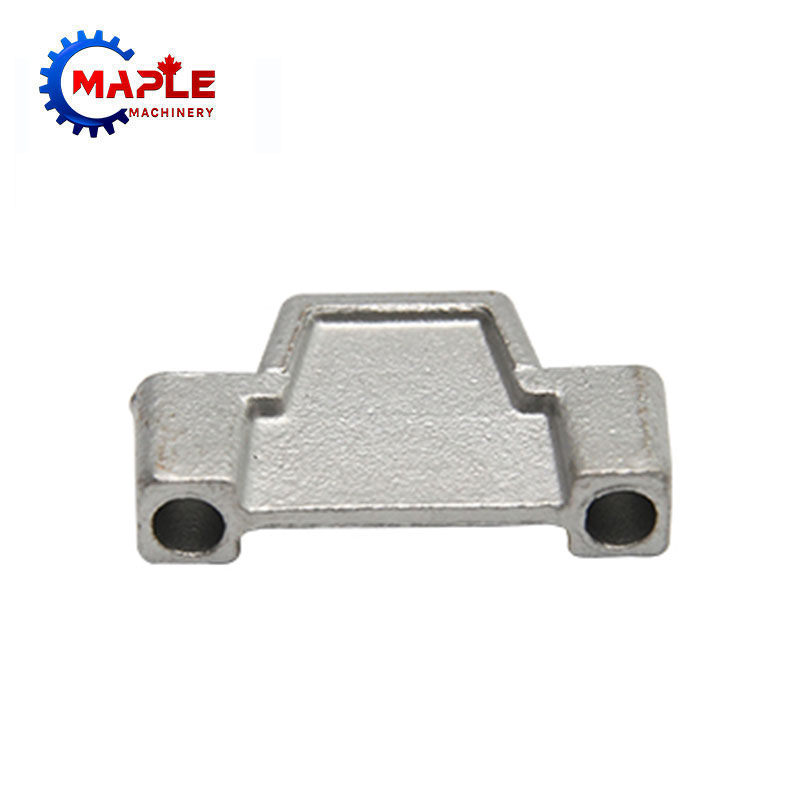

Visokokakovostni uliti, strojno obdelani deli po konkurenčnih cenah zanesljivih dobaviteljev. Maple Machinery je znan proizvajalec kovinskih delov na Kitajskem in zanesljiv dobavitelj strojev za predelavo hrane. Stroj za predelavo hrane zahteva visoko natančne dele za litje železa v pesek. Sposobni smo dobro opraviti delo večjih dobaviteljev izdelkov vseh pomembnih komponent sistema.Deli za vlivanje iz jeklenega ventila

Na področju javorjevih strojev imamo obsežne izkušnje z litjem za dele za vlivanje iz ventilnega jekla, kar našim strankam omogoča pridobitev visokokakovostnih ulitkov iz procesa vlitja po ekonomični ceni. Imamo odlično tehnično ekipo z dolgoletnimi izkušnjami, ki vam zagotavlja najboljše načrte za vlivanje. Kakršna koli potrebna pomoč – od preprostih pregledov toleranc do popolnega sočasnega inženiringa – je na voljo na naši livarni. Deli za vlivanje iz jeklenega ventila, javorjevi stroji vam lahko zagotovijo najboljše.Industrijski deli za litje železa v pesek

Maple machinery je proizvajalec industrijskih delov za litje železa v pesek, specializiran za proizvodnjo različnih vrst ulitkov. Vsaka članica ima svoje specifično znanje in proizvodno tehnologijo. Vse livarne imajo svojo samostojno dejavnost. Podjetje izdeluje dele za litje železa v pesek po meri za globalne strankeDeli za vlivanje iz jekla za pomorstvo

Stroji Maple imajo profesionalno livarsko opremo in bogate izkušnje pri litju in obdelavi jeklenih vložkov. Hkrati imamo lastne edinstvene načine za dobro izdelavo delov za vlivanje iz jekla za pomorstvo. Investicijski ulitek je izbran, ker vložni ulitek v veliki meri odpravlja potrebo po sekundarni obdelavi ter pomaga strankam prihraniti stroške in skrajšati proizvodni čas.

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy