Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

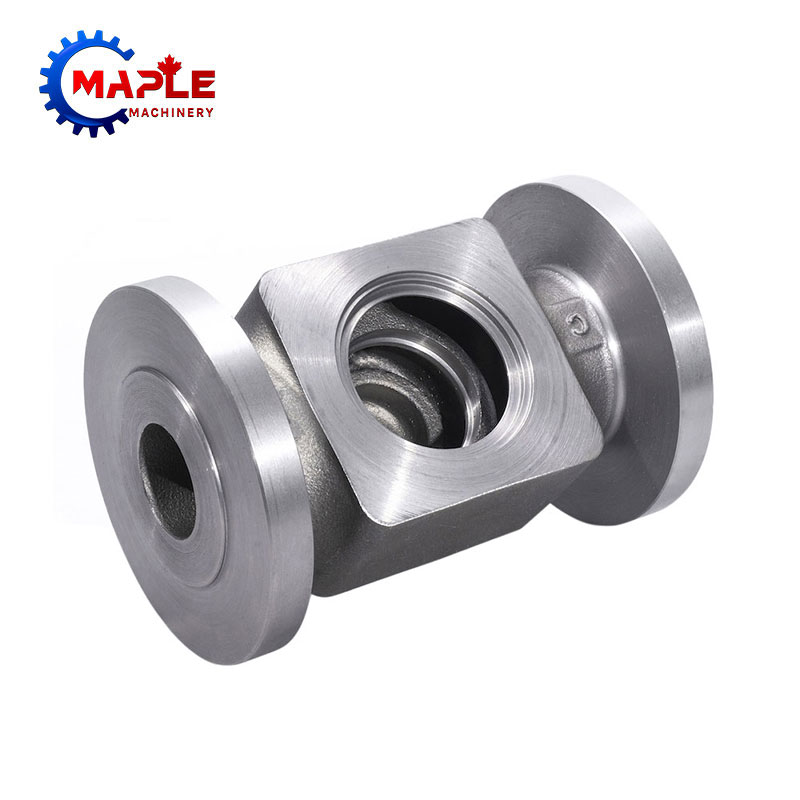

Sestavni deli jeklene litine za rudarsko industrijo Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

Deli za ulivanje jekla v naftni in plinski industriji

Maple je ISO certificiran livarski in predelovalni obrat z bogatimi izkušnjami na področju proizvodnje delov za ulivanje jekla v naftni in plinski industriji. Naši strokovnjaki za investicijsko litje vam bodo nudili vso pomoč, od odpravljanja težav pri načrtovanju do izbire prave zlitine za vaše delovno okolje.Deli iz nodularnega litega železa

Maple machinery s svojim obsežnim tehničnim znanjem in visoko usposobljeno ekipo razvija prilagojene rešitve za dele iz nodularnega litega železa v skladu s potrebami naših strank. Dajanje prednosti zaupnosti, odgovornosti in trajnosti v odnosih z vsemi zainteresiranimi stranmi, ob upoštevanju srednjeročnih in dolgoročnih ciljev podjetja Valve. Tehnične zahteve, določene v dogovoru s stranko, zagotavljajo prilagojene storitve. Servisna ekipa si prizadeva za hiter odziv in neposredno preglednost od razvoja projekta do poprodaje. Zagotovite rešitve za ulivanje v skladu z zahtevami in specifikacijami kupcev.Deli za litje ventilskega železa

Maple machinery že več kot 15 let izdeluje dele za litje ventilskega železa v pesek in je proizvajalec kovin s sedežem v Ningboju na Kitajskem. Cilj je bil ustvariti podjetje s tehničnim in metalurškim ozadjem v proizvodnji kovin in kovinskih delov. Ponosni smo, da smo lahko zadnjih 15 let učinkovito služili našim globalnim strankam. Od takrat smo svoje izkušnje in tehnično znanje izkoristili za izpolnjevanje zahtev naših številnih zadovoljnih strank v Združenih državah, Kanadi in Severni Ameriki.Odkovki iz nerjavečega jekla za kmetijske stroje

Maple ima več kot 15 let izkušenj pri izdelavi kovanih izdelkov za kmetijsko mehanizacijo. Odkovki iz nerjavečega jekla za kmetijske stroje. S predelavo avtomatskih izdelkov lahko izdelujemo natančne kmetijske kovaške izdelke. Zadovoljite različne potrebe strank. Zagotavljamo učinkovitost naših izdelkov. Po drugi strani pa v okviru vpogleda v kupce in trg skrbno načrtujemo, da bomo ohranili celovitost dobavne verige in se v najboljšem stanju odzvali na potrebe kupcev.Deli za ulivanje iz izgubljenega voska za gradbene stroje

Vsi deli strojev Maple za jeklene litine iz izgubljenega voska za gradbene stroje so izdelani z notranjo trdnostjo in celovitostjo. S prefinjenim postopkom Lost Wax Casting lahko izdelamo dele s strogimi tolerancami. Stroji Maple uporabljajo programsko opremo za modeliranje strjevanja za napovedovanje notranje ravni kakovosti ulitkov, preden so deli izdelani, kar močno skrajša čas do trga in stroške razvoja s pristopom "poskusov in napak" pri razvoju procesa.Deli za natančno litje jekla v industriji recikliranja

Maple machinery že od nekdaj zagotavlja najvišjo kakovost storitev za predelavo jeklenih delov za natančno litje po naročilu. Našim strankam zagotavljamo najvišjo raven kakovosti delov in storitev. Naša storitev predelave jeklenih delov za natančno litje v industriji recikliranja je zasnovana tako, da ustreza natančnim potrebam naših strank, naša ekipa pa je predana zagotavljanju vrednosti z natančnim inženiringom in inovativnimi zmožnostmi orodij.

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy