Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

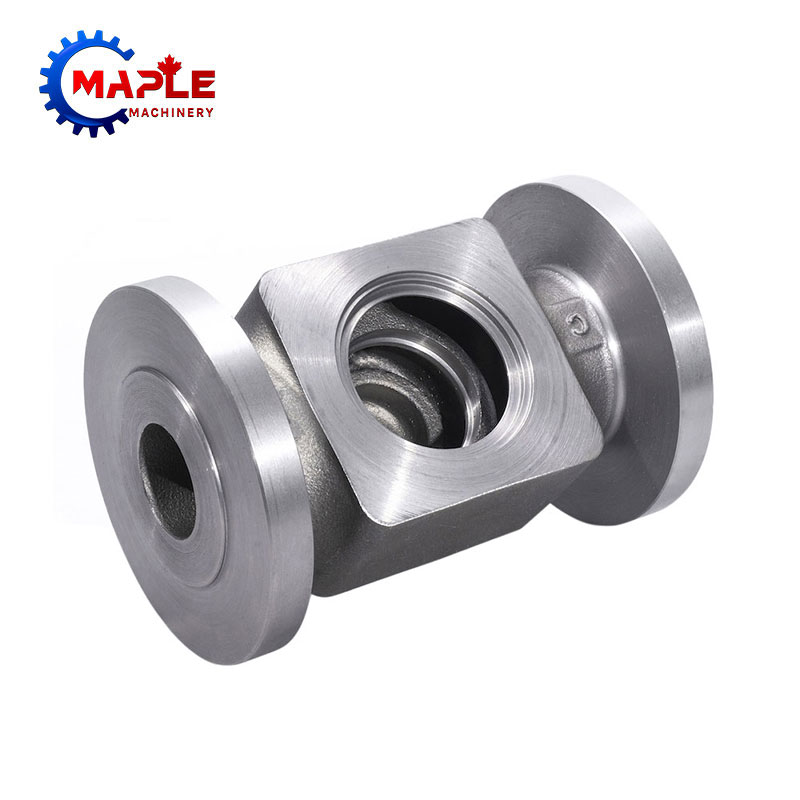

Precizno uliti deli za ventile Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

Deli za ulivanje jekla v naftni in plinski industriji

Maple je ISO certificiran livarski in predelovalni obrat z bogatimi izkušnjami na področju proizvodnje delov za ulivanje jekla v naftni in plinski industriji. Naši strokovnjaki za investicijsko litje vam bodo nudili vso pomoč, od odpravljanja težav pri načrtovanju do izbire prave zlitine za vaše delovno okolje.Odkovki jeklenih delov za mornarje

Kovanje jekla je glavna vrsta kovinskega kovanja tehnologija oblikovanja jekla, ki uporablja lokalno stiskalno silo. Odkovki so bili podvrženi pomembnim spremembam, kar je privedlo do učinkovitejših, hitrejših in dolgotrajnejših procesov. Dandanes se ladijski jekleni kovani deli običajno izdelujejo z električnimi, hidravličnimi ali kovaškimi stiskalnicami ali udarnimi orodji na stisnjen zrak. Vroče kovanje vključuje segrevanje obdelovanca na približno 75 % temperature taljenja.Deli za litje iz nerjavečega jekla za naftno in plinsko industrijo

Stroji Maple obdelujejo vse vrste kovin in naše izkušnje nam omogočajo enostavno dokončanje proizvodnje delov za litje iz nerjavečega jekla za naftno in plinsko industrijo Nerjaveče jeklo je eden od običajnih materialov v našem laboratoriju. Omogoča nam zagotavljanje celovitih storitev preko partnerstev ter zagotavljanje tehničnih in ekonomskih rešitev z zagotavljanjem prilagodljivih, raznolikih virov dobave. Interno integrirajte celotno proizvodno verigo, da zagotovite odzivnost, tehnično mojstrstvo in kakovost. In predlogi za ekonomsko optimizacijo.Deli za natančno litje jekla v industriji recikliranja

Maple machinery že od nekdaj zagotavlja najvišjo kakovost storitev za predelavo jeklenih delov za natančno litje po naročilu. Našim strankam zagotavljamo najvišjo raven kakovosti delov in storitev. Naša storitev predelave jeklenih delov za natančno litje v industriji recikliranja je zasnovana tako, da ustreza natančnim potrebam naših strank, naša ekipa pa je predana zagotavljanju vrednosti z natančnim inženiringom in inovativnimi zmožnostmi orodij.Deli za vlivanje iz jekla za težko industrijo

Stroji Maple imajo dolgo zgodovino na področju delov za vlivanje jekla v težki industriji in strokovno moč, pridobljeno iz zgodovine in sodobnih metod upravljanja, da dosežejo odlično komplementarnost in integracijo. Zdaj je tehnologija z nenehnimi inovacijami in razvojem dosegla visok skok.Hidravlični sistem Jekleni zaprti kovani deli

Maple stroji nenehno izboljšujejo in prizadevanja, oprema je bila pripravljena za množično proizvodnjo. Zaprti kovani deli hidravličnega sistema iz jekla so bili s pomočjo sledenja in raziskav stranke funkciji, stabilnosti kakovosti, mehanskemu nadzoru in natančnosti krmiljenja opreme soglasno potrjeni s strani stranke jeklenega hidravličnega sistema. Z razvojem produktivnosti ter napredkom znanosti in tehnologije igrajo naši učinkoviti stroji vse pomembnejšo vlogo v proizvodnih podjetjih za izboljšanje učinkovitosti in izboljšanje kakovosti izdelkov.

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy