Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

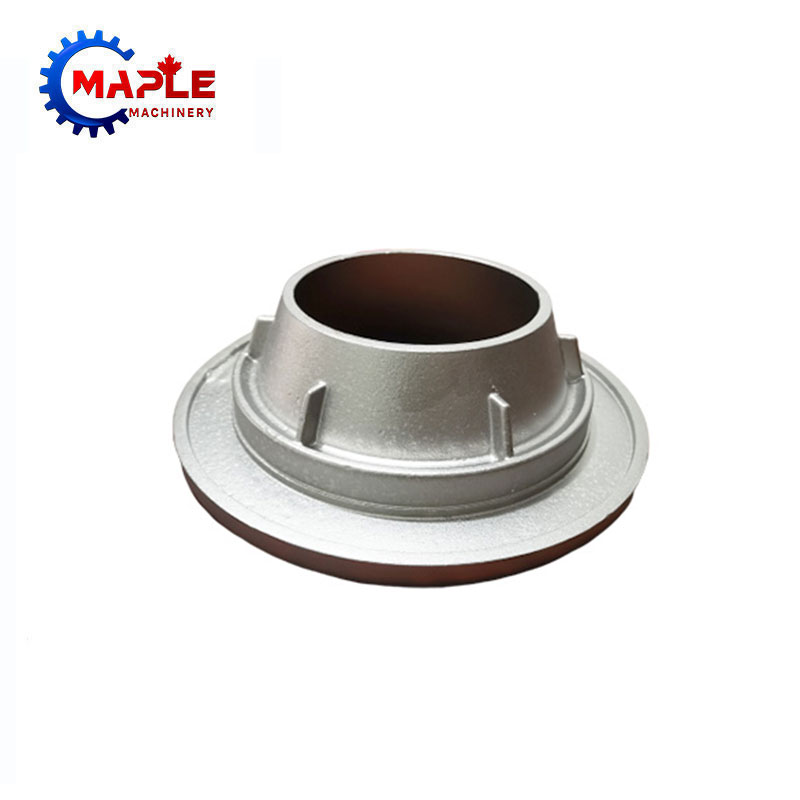

Livarne delov za ulivanje ventilov in črpalk Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

Gradbeni deli za litje iz nerjavečega jekla

Maple machinery je dobavitelj delov za ulivanje iz nerjavečega jekla v gradbeništvu, ki proizvaja kompleksne ulitke z izjemno visoko natančnostjo z uporabo metode "izgubljenega voska". Zaradi tega splošnega pristopa imajo naši inženirji veliko svobode pri oblikovanju izdelka in izbiri materiala. To pomeni, da lahko v dogovoru z vami izdelamo najboljši odlitek, ki natančno ustreza vašim željam in zahtevam. Maple machinery je vaš razvojni partner za uspešno litje s ciljem izdelave najboljšega livarskega izdelka z medsebojnim posvetovanjem.Deli za litje sive litine v težki industriji

Maple machinery je proizvajalec delov za litje sive litine v težki industriji, specializiran za proizvodnjo različnih vrst ulitkov. Vsaka članica ima svoje specifično znanje in proizvodno tehnologijo. Vse livarne imajo svojo samostojno dejavnost. Podjetje izdeluje dele za litje železa v pesek po meri za globalne strankeJekleni kovaški deli za kmetijske stroje

Maple Machinery Co., Ltd., ki se nahaja v Ningboju na Kitajskem, je že več kot 20 let profesionalni proizvajalec zaprtih odkovkov, specializiran za zagotavljanje visokokakovostnih jeklenih delov za kovanje kmetijskih strojev. Poleg tega lahko nudimo tudi druge storitve z dodano vrednostjo za končne izdelke. Zato, če potrebujete kovanje in strojno obdelane dele, nas kontaktirajte!Kovani deli ventila iz nerjavečega jekla

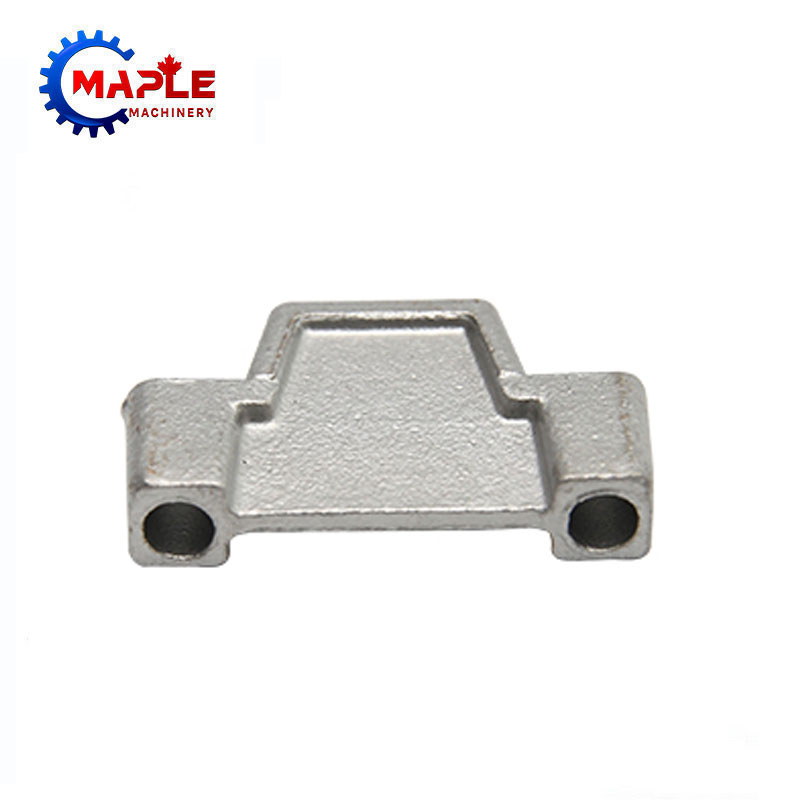

Obdelava delov za kovanje ventilov iz nerjavečega jekla Imamo vse običajne tehnike za kovanje delov. Obseg naših storitev zajema obdelavo nerjavnih odkovkov, predvsem rezkanje in struženje na CNC obdelovalnih strojih. Glede na zahteve strank lahko zagotovimo tudi sodelovanje z drugimi tovarnami.Gradbeni stroji Jekleni zaprti kovani deli

Jeklene dele zaprtega kovanja Maple's Construction Machinery uporabljajo proizvajalci gradbenih strojev v Združenih državah in Evropi. Je del hidravličnega cilindra bagra, spojni del izkopnega manipulatorja in del krmilnega krmilnega sistema v velikih gradbenih strojih. Je najpomembnejši del gradbenih strojev. Deli zaprtega kovanja za gradbene stroje našega podjetja so izdelani iz legiranega jekla visoke trdnosti, proizvodni proces pa je napreden proces kovanja kovin. Notranji materiali odkovkov so dobro organizirani in brez napak, kar lahko zadosti potrebam visoko trdnega delovanja gradbenih strojev. Je prednostna komponenta za izdelavo visokokakovostnih gradbenih strojev.Deli za litje izgubljenega voska za jeklo za težko industrijo

Prek robustnega sistema vodenja kakovosti, brezkompromisnega upoštevanja uveljavljenih standardov, neusmiljene osredotočenosti na natančnost in nenehnega prizadevanja za izboljšave in zadovoljstvo strank – vse to so elementi, ki nam pomagajo pri zagotavljanju najkakovostnejših delov za ulivanje izgubljenega voska za jeklo za težko industrijo našim strankam po vsem svetu.

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy