Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

Deli za vlivanje iz jekla za gradbeništvo Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

Deli za litje iz nerjavečega jekla za predelavo hrane

Strojni inženirji podjetja Maple za Food Process Machine delujejo kot razširitev vaše organizacije pri razvoju preciznega litja. Z vedno premislekom, ali bi lahko bile stvari »tehnično boljše, drugačne, cenejše in/ali enostavnejše«, dobimo najboljšo rešitev po konkurenčni ceni. Z veseljem delimo svoje znanje o tehnikah litja z vami, da oblikujemo najboljše dele za litje iz nerjavečega jekla za stroje za predelavo hrane.Naftna in plinska industrija Deli za ulivanje železa v pesek

Maple Machinery ima spretnosti in izkušnje za zagotavljanje preciznih delov za ulivanje železa v pesek v naftni in plinski industriji za uporabo v nafti in plinu. Ti ulitki so ves čas izpostavljeni težkim delovnim pogojem, zato morajo biti ti ulitki dovolj vzdržljivi, da lahko delujejo pri visoki temperaturi in visoki trdnosti. Z našo napredno tehnologijo litja lahko izdelamo dele v mrežni obliki ali skoraj neto obliki, kar zagotavlja odlično odpornost proti koroziji, trdnost in odpornost proti obrabi.Deli za naložbeno ulivanje jekla izven avtocestne industrije

Maple Machinery uporablja profesionalno tehnologijo in strokovno znanje za načrtovanje in proizvodnjo visokokakovostnih izdelkov. Uporabljamo precizne ulitke, ki jih proizvajamo v hitrih železnicah po vsem svetu. Sodelujemo in sodelujemo z več velikimi proizvajalci železniških delov po svetu. Naše stranke zaradi naših izčrpnih standardov nadzora kakovosti z zaupanjem uporabljajo naše dele za ulivanje jekla izven avtocestne industrije. Zagotavljamo, da so jekleni ulitki in odkovki, ki jih izdelamo za industrijo izven avtocest, zanesljivi.Deli za litje sive litine za gradbene stroje

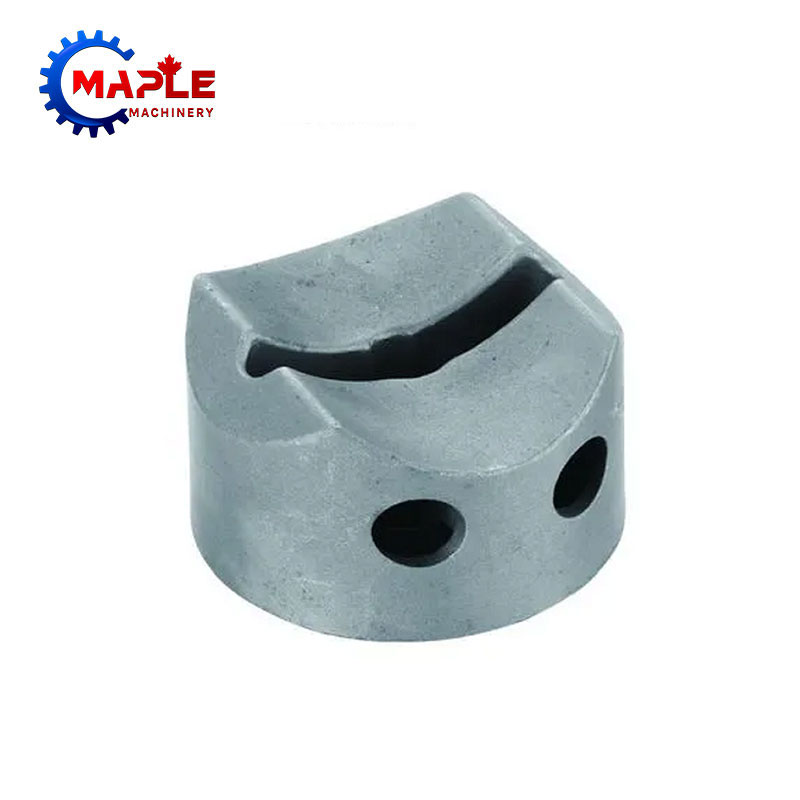

Deli za litine iz sive litine so pogosti kovinski ulitki v dejavnostih obdelave kovin. Postopek vključuje taljenje materiala iz litega železa in polnjenje staljene tekočine v kalup, da se oblikuje ulitek. Lito železo ima zelo dolgo tradicijo, ki sega v leto 1200 pr. n. št., danes pa ulitki iz litega železa močno prispevajo k različni življenjski uporabi gradbenih strojev. Vidimo lahko, da obstaja veliko izdelkov iz litine iz litega železa in delov za litine iz sivega železa za gradbene stroje.Kovani deli iz nerjavečega jekla v gradbeništvu

Pomen nosilcev iz nerjavečega jekla v širokem svetu gradbeništva, inženiringa, gradbenega in konstrukcijskega jekla. Kovani nosilci iz nerjavečega jekla so že več kot 15 let pomemben del gradbeništva. Kot dobavitelj delov iz nerjavečega jekla Maple machinery proizvaja različne dele za kovanje iz nerjavečega jekla v gradbeništvu, ki jih je za vas prilagodila naša ekipa. Smo zaupanja vreden proizvajalec vaših delovDeli za natančno litje jekla hidravličnega sistema

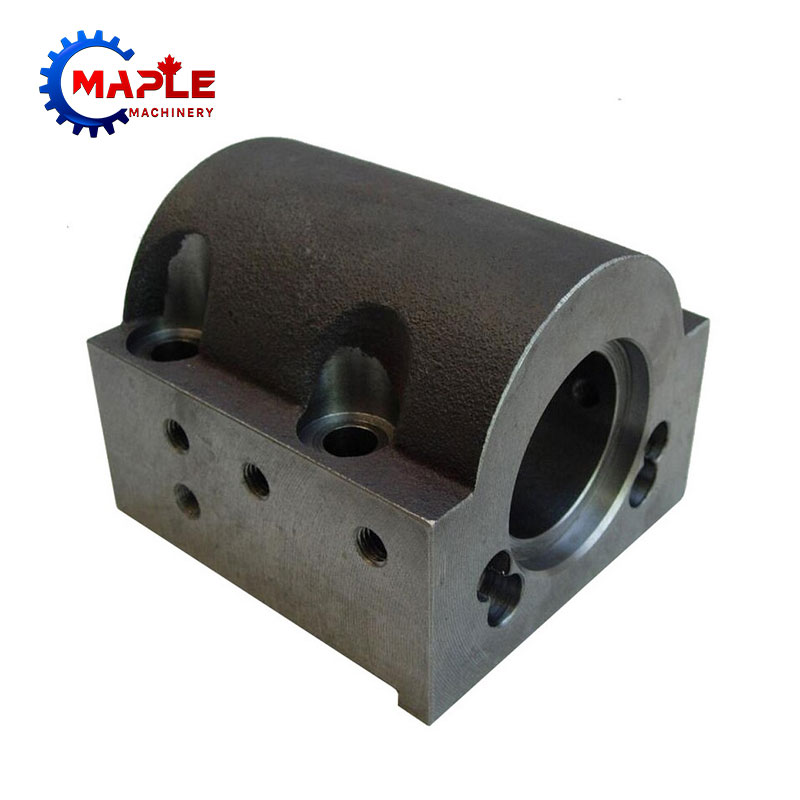

Stroji Maple imajo močan tehnološki razvoj in inovacijske zmogljivosti za izpolnjevanje proizvodnih zahtev hidravličnih sistemov jeklenih delov za natančno litje. Aktivno smo sodelovali z izjemnimi mednarodnimi podjetji, da bi izdelali serijo jeklenih delov za natančno litje hidravličnega sistema s konkurenčnimi prednostmi. Podjetje ima močno tehnično silo, popolno profesionalno opremo, strog nadzor kakovosti. Naše podjetje se dobro zaveda, da konkurenca izdelkov temelji na razvoju novih izdelkov, človeški ustvarjalnosti in nadzoru kakovosti, zato razvijamo konkurenčne izdelke s sistematično strategijo upravljanja in kopičenjem tehnologije.

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy