Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

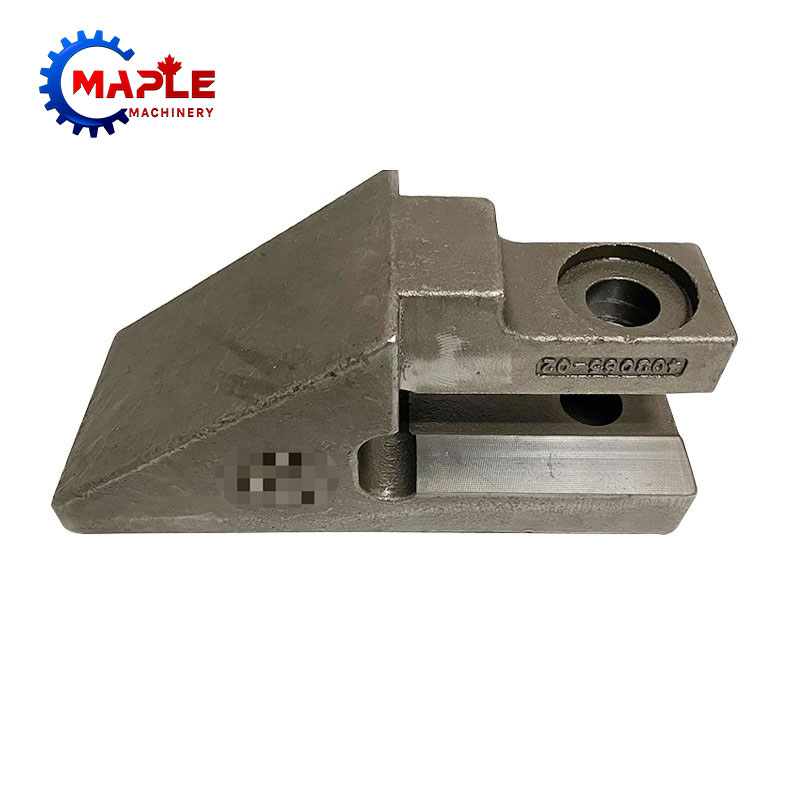

Sestavni deli za rudarjenje nodularne litine Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

Deli za ulivanje jekla za kmetijske stroje

Maple Machinery je v kmetijsko industrijo vdrl pred več leti, danes pa ima širok in uspešen trg v Evropi in Severni Ameriki. Imamo vedno večji seznam zvestih strank, ki se zanašajo na visokokakovostne dele za ulivanje jekla za kmetijske stroje za svojo kmetijsko industrijo. Zaupanje strank si lahko pridobimo le s svojimi strokovnimi storitvami in visokokakovostnimi izdelki, ki temeljijo na naprednih tehnologijah.Industrija recikliranja Deli za kovanje iz nerjavečega jekla

V prizadevanju za bolj trajnosten svet se je Recycling Industry Stainless Steel Forging Parts izkazal za dragocenega zaveznika za arhitekte, inženirje in izvajalce, s številnimi koristmi ne samo za projekte, ampak za družbo kot celoto. Prednosti uporabe recikliranih industrijskih odkovkov iz nerjavečega jekla vključujejo zmanjšane stroške projekta ter večjo estetiko, zanesljivost in predvidljivost. Z vidika trajnosti lahko kombinacija nerjavečega jekla z naprednimi materialnimi tehnologijami doseže nove višine.Gradbeni deli iz sive litine

Kot odgovor na pričakovanja kupcev Maple machinery ponuja široko paleto gradbenih litin iz sivega železa in številne druge industrijske kovinske dele. Sodelujemo s številnimi livarnami, saj lahko zagotovimo posamezne in specifične projekte ter celotne serije. Vsaka jeklarna, s katero sodelujemo, je natančno preverjena. Nadzorujemo kakovost ognjevarnih materialov, da zagotovimo kakovostne in visokostandardne ulitke, ki jih pričakujejo naše stranke.Deli za litje ventilskega železa

Maple machinery že več kot 15 let izdeluje dele za litje ventilskega železa v pesek in je proizvajalec kovin s sedežem v Ningboju na Kitajskem. Cilj je bil ustvariti podjetje s tehničnim in metalurškim ozadjem v proizvodnji kovin in kovinskih delov. Ponosni smo, da smo lahko zadnjih 15 let učinkovito služili našim globalnim strankam. Od takrat smo svoje izkušnje in tehnično znanje izkoristili za izpolnjevanje zahtev naših številnih zadovoljnih strank v Združenih državah, Kanadi in Severni Ameriki.Gradbeni deli za litje železa v pesek

Od ustanovitve podjetja se je Maple machinery Iron Sand Casting Parts že od prvega dne specializiral za proizvodnjo visokokakovostnih in kompleksnih železnih ulitkov za številne industrije. Našim strankam nudimo celovite rešitve za aluminijaste komponente. V naši organizaciji izvajamo vse podprocese, povezane s proizvodnjo kompleksnih ulitkov. To zagotavlja celovito interno rešitev gradbenih delov za litje železa v pesek, kjer imajo stranke koristi od vrhunske kakovosti in zanesljivosti, ki ju imajo pravico pričakovati od svojih dobaviteljev delov za litje železa v pesek.Deli za ulivanje jekla v pesek izven avtoceste

Stroji Maple imajo dolgo in ponosno zgodovino jeklenega litja v pesek na Kitajskem, s čimer postavljajo merilo za dele za jekleno litje v pesek zunaj avtocestne industrije. Od svoje ustanovitve se Maple machinery osredotoča na prodajo delov za jeklene litine v pesek za industrijo zunaj avtocest. Z več kot 15-letnimi izkušnjami v livarni ter obsežno proizvodno in distribucijsko mrežo smo na čelu panoge v smislu kakovosti izdelkov, inovacij, tehnične podpore in storitev za stranke.

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy