Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

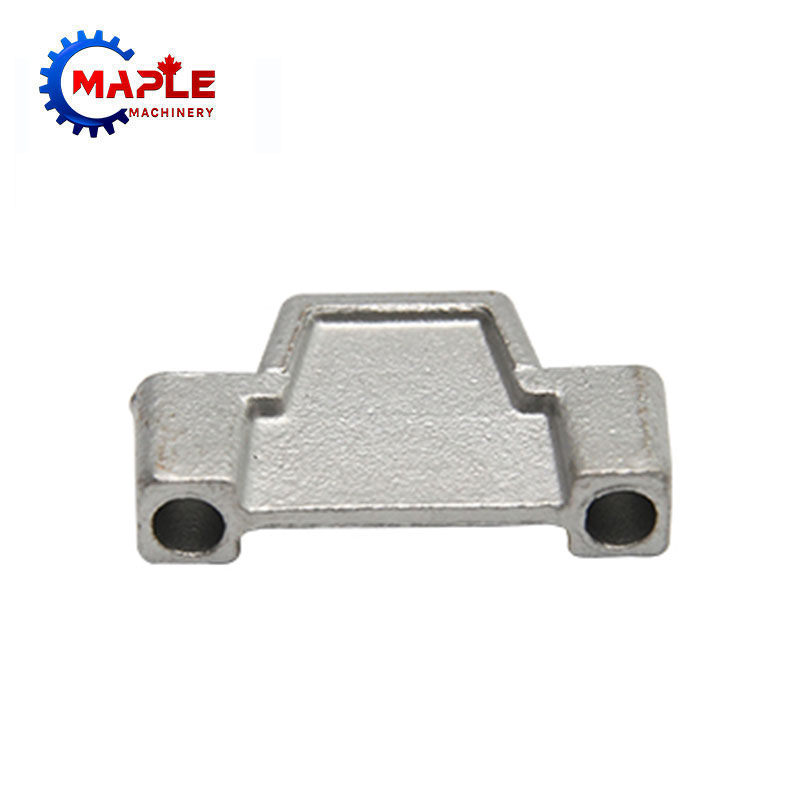

Deli za natančno litje jekla v težki industriji Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

Deli za ulivanje iz nodularne litine za zunajcestno industrijo

Če izberete stroje Maple, izberete izkušenega proizvajalca litin iz nodularne litine, ki je strasten do svojega poklica. Maple machinery ima skoraj 20 let izkušenj z razvojem in proizvodnjo delov za ulivanje iz nodularne litine za zunajcestno industrijo. Vsak korak podjetja Ductil Iron Casting se zaveda, da gresta strast in kakovost z roko v roki. Na ta način se vsak dan razvija kot ekipa, močna kot železo.Hidravlični kolektorji iz litega železa

Maple Machinery stoji kot zaupanja vreden mednarodni zaveznik na področju litoželeznih hidravličnih razdelilnikov. Naše ponudbe se široko uporabljajo v različnih panogah, kot so avtomobilska, kemična, gradbena in rudarska. Kar nas loči od drugih, je naš celovit pristop k storitvam. Nismo le specializirani za proizvodnjo ulitkov, ampak se odlikujemo tudi na področju strojne in toplotne obdelave, s čimer bistveno poenostavimo postopek izpolnjevanja naročil in zagotovimo hitro dostavo. Ta model celovitih storitev poudarja našo zavezanost učinkovitosti in zadovoljstvu strank.Industrija recikliranja Deli za kovanje iz nerjavečega jekla

V prizadevanju za bolj trajnosten svet se je Recycling Industry Stainless Steel Forging Parts izkazal za dragocenega zaveznika za arhitekte, inženirje in izvajalce, s številnimi koristmi ne samo za projekte, ampak za družbo kot celoto. Prednosti uporabe recikliranih industrijskih odkovkov iz nerjavečega jekla vključujejo zmanjšane stroške projekta ter večjo estetiko, zanesljivost in predvidljivost. Z vidika trajnosti lahko kombinacija nerjavečega jekla z naprednimi materialnimi tehnologijami doseže nove višine.Deli za jeklene litine za ventile

Nadzor kakovosti s stroji Maple je zelo strog. Valve Steel Casting Parts je izdelek, ki ga vsako leto proizvedemo v velikih količinah, vendar stroji Maple nikoli ne popustijo. Sistem preverjanja kakovosti in varnosti se uporablja v vseh delavnicah. Občasno preverite zanesljivost vseh testerjev in merilnih instrumentov ter usposobljenost delavcev. Potrebno je nadzorovati proizvodni načrt in narediti neporušitveno testiranje glavno sredstvo nadzora kakovosti.Deli za ulivanje jekla za kmetijske stroje

Maple Machinery je v kmetijsko industrijo vdrl pred več leti, danes pa ima širok in uspešen trg v Evropi in Severni Ameriki. Imamo vedno večji seznam zvestih strank, ki se zanašajo na visokokakovostne dele za ulivanje jekla za kmetijske stroje za svojo kmetijsko industrijo. Zaupanje strank si lahko pridobimo le s svojimi strokovnimi storitvami in visokokakovostnimi izdelki, ki temeljijo na naprednih tehnologijah.Hidravlični sistem Jekleni deli za naložbeno ulivanje

Maple je ključni akter v procesni industriji na področju natančnega investicijskega litja. Maple je razvil številne hidravlične dele jekla za naložbeno ulivanje, ki so običajno vliti v posebne zlitine. Te posebne zlitine se uporabljajo, ker komponente običajno delujejo v okoljih, ki so korozivna (ostra), imajo velike temperaturne razlike ali zahtevajo zelo trde, močne ali lahke izdelke.

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy