Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

Industrijsko litje sive litine Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

Deli za natančno litje jekla za naftno in plinsko industrijo

Stroji Maple so bili predani oskrbi trga na morju z deli za natančno litje jekla za naftno in plinsko industrijo. Deli za natančno litje jekla veljajo za bistvenega pomena za pridobivanje nafte in plina - obroči iz legiranega jekla, ohišja, mehanske cevi - ki se uporabljajo za ustvarjanje mokre proizvodnje. Da bi zadovoljili povpraševanje domačega in mednarodnega trga, podjetje vlaga v dodatne proizvodne zmogljivosti.Deli za litje železa v pesek za predelavo hrane

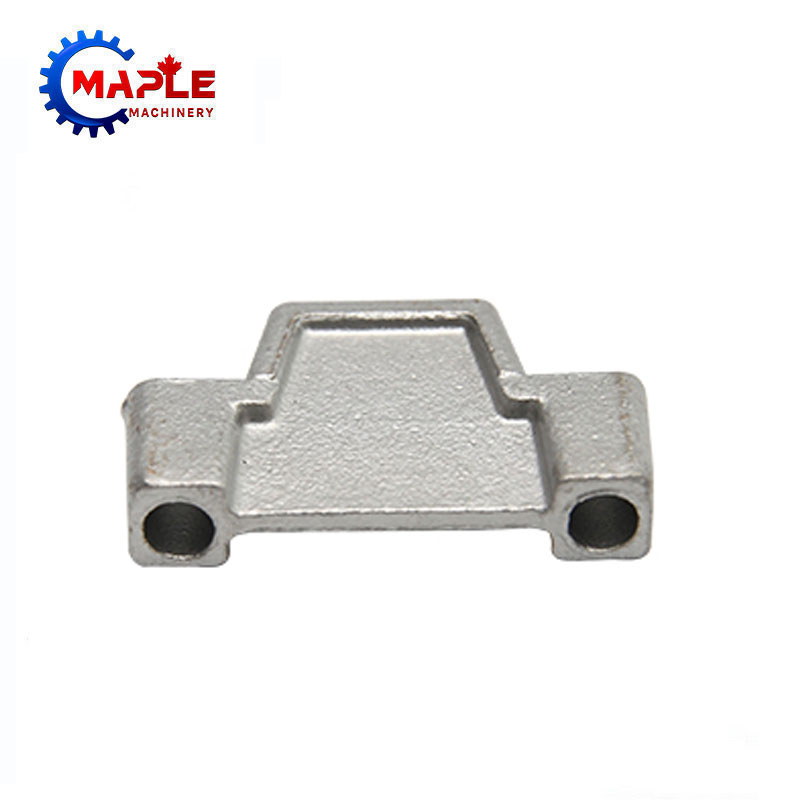

Visokokakovostni uliti, strojno obdelani deli po konkurenčnih cenah zanesljivih dobaviteljev. Maple Machinery je znan proizvajalec kovinskih delov na Kitajskem in zanesljiv dobavitelj strojev za predelavo hrane. Stroj za predelavo hrane zahteva visoko natančne dele za litje železa v pesek. Sposobni smo dobro opraviti delo večjih dobaviteljev izdelkov vseh pomembnih komponent sistema.Deli za ulivanje jekla v naftni in plinski industriji

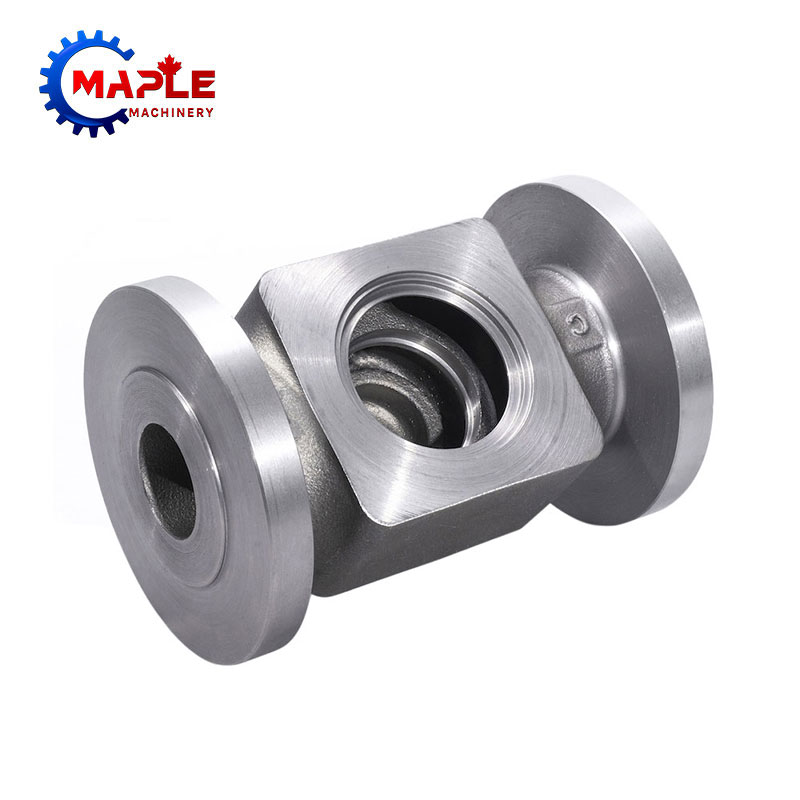

Maple je ISO certificiran livarski in predelovalni obrat z bogatimi izkušnjami na področju proizvodnje delov za ulivanje jekla v naftni in plinski industriji. Naši strokovnjaki za investicijsko litje vam bodo nudili vso pomoč, od odpravljanja težav pri načrtovanju do izbire prave zlitine za vaše delovno okolje.Deli za litje izgubljenega voska iz jekla hidravličnega sistema

Maple machinery vlaga v sodobno in sofisticirano opremo, da bi izpolnil vse zahteve kupcev za dele za litje iz izgubljenega voska iz jekla hidravličnega sistema v smislu zanesljivosti, ponovljivosti in prilagodljivosti. Maple machinery ima bogate izkušnje z ulivanjem po izgubljenem vosku in industrijskimi certifikati, ki se vsakič posodobijo in izboljšajo.Naftna in plinska industrija Jekleni zaprti kovani deli

Maple Machinery je podjetje, ki že 20 let zagotavlja rešitve za kovanje. Prešli smo certifikat ISO9001. Brez napak je del naših proizvodnih standardov in zagotavljamo, da se vsi procesi vzdržujejo v podjetju s prvovrstno infrastrukturo. Ponosni smo na naše izkušnje in odprto komunikacijo z dobavitelji za razvoj zaprtih delov za kovanje jekla za naftno in plinsko industrijo, izpolnjevanje standardov oblikovanja strank in zagotavljanje hitre dostave visokokakovostnih izdelkovOdkovki iz nerjavečega jekla za naftno in plinsko industrijo

Stroji Maple se nahajajo v Ningboju na Kitajskem za proizvodnjo delov, skladiščenje in podprevoz delov za kovanje iz nerjavečega jekla za naftno in plinsko industrijo ter so v dobrem položaju, da izpolnjujejo potrebe glavnih dobaviteljev v naftni in plinski industriji. V kombinaciji s certificiranimi in odobrenimi dobavitelji naših strank v več državah imate priložnost izkoristiti prednosti nizkocenovne nabave iz države in vedeti, da je zahvaljujoč Mapleovim izdelkom 100-odstotno jamstvo kakovosti

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy