Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

Industrija recikliranja Deli za litje izgubljenega voska iz jekla Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

Kovani deli ventila iz nerjavečega jekla

Obdelava delov za kovanje ventilov iz nerjavečega jekla Imamo vse običajne tehnike za kovanje delov. Obseg naših storitev zajema obdelavo nerjavnih odkovkov, predvsem rezkanje in struženje na CNC obdelovalnih strojih. Glede na zahteve strank lahko zagotovimo tudi sodelovanje z drugimi tovarnami.Deli za litje iz nerjavečega jekla v industriji recikliranja

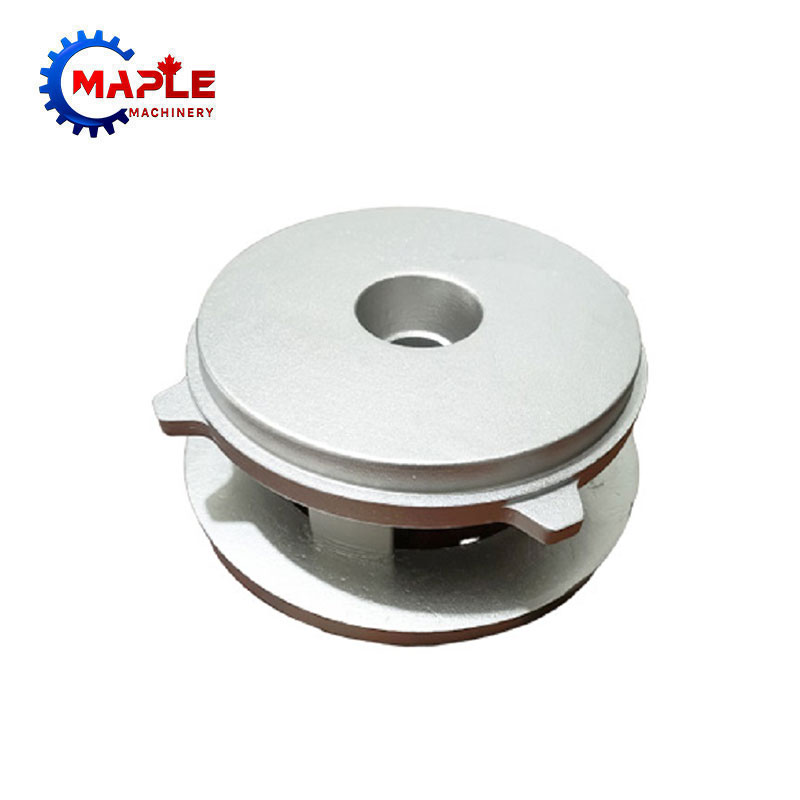

Stroji Maple uporabljajo najnovejšo tehnologijo v našem postopku ulivanja za naložbe, da stroškovno učinkovito in pravočasno izdelajo visokokakovostne dele za ulivanje iz nerjavečega jekla v industriji recikliranja. Nenehno iščemo nove tehnologije in inovativne načine za izboljšanje našega procesa vlitja v reciklirani industriji, našo učinkovitost, našo kakovost in skrajšanje našega dobavnega časa.Industrija recikliranja litin iz nodularne litine

Maple machinery deluje na trgu že vrsto let in je zanesljiv partner domačim in tujim izvajalcem. Industrija recikliranja Liti deli iz nodularne litine, ki jih proizvajamo, se pogosto uporabljajo v industriji recikliranja. Naša prednost je celovita storitev - zagotavljamo izdelavo specializiranih ulitkov ter strojno in toplotno obdelavo, s čimer močno skrajšamo čas izvedbe naročila. Imamo lastno modelarno, kjer izdelujemo lesene in smolne modele. Imamo dobro opremljeno livarno in sodobno proizvodno linijo brez kalupov za steklenice.Deli za natančno litje jekla za naftno in plinsko industrijo

Stroji Maple so bili predani oskrbi trga na morju z deli za natančno litje jekla za naftno in plinsko industrijo. Deli za natančno litje jekla veljajo za bistvenega pomena za pridobivanje nafte in plina - obroči iz legiranega jekla, ohišja, mehanske cevi - ki se uporabljajo za ustvarjanje mokre proizvodnje. Da bi zadovoljili povpraševanje domačega in mednarodnega trga, podjetje vlaga v dodatne proizvodne zmogljivosti.Deli za litje izgubljenega voska za jeklo za težko industrijo

Prek robustnega sistema vodenja kakovosti, brezkompromisnega upoštevanja uveljavljenih standardov, neusmiljene osredotočenosti na natančnost in nenehnega prizadevanja za izboljšave in zadovoljstvo strank – vse to so elementi, ki nam pomagajo pri zagotavljanju najkakovostnejših delov za ulivanje izgubljenega voska za jeklo za težko industrijo našim strankam po vsem svetu.Industrija recikliranja Deli za litine iz sivega litina

Maple stroji Postopek litja v pesek proizvaja dele za litje iz sivega železa v industriji recikliranja. Peščeni kalupi so narejeni iz lesa ali kovinskih vzorcev. Drobnozrnati pesek je bil zmešan s smolnim vezivom v visokohitrostnem mešalniku in vsut v vzorčaste škatle. Po nekaj minutah se je mešanica peska in lepila strdila in kalup je bil odstranjen iz vzorca. Enak postopek se uporablja za jedra, ki se uporabljajo za izdelavo notranje strukture ulitka.

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy