Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

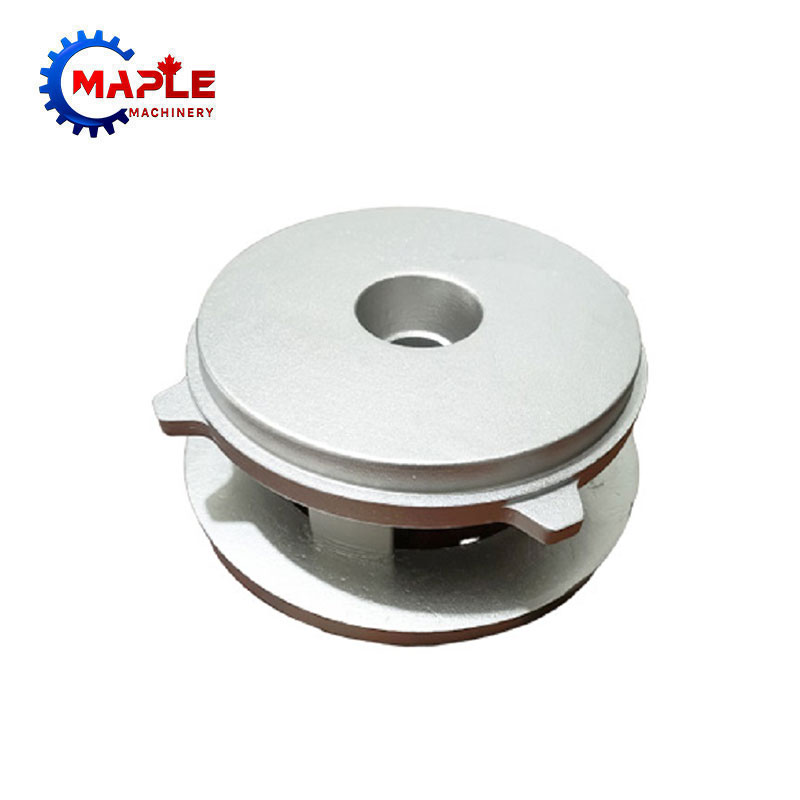

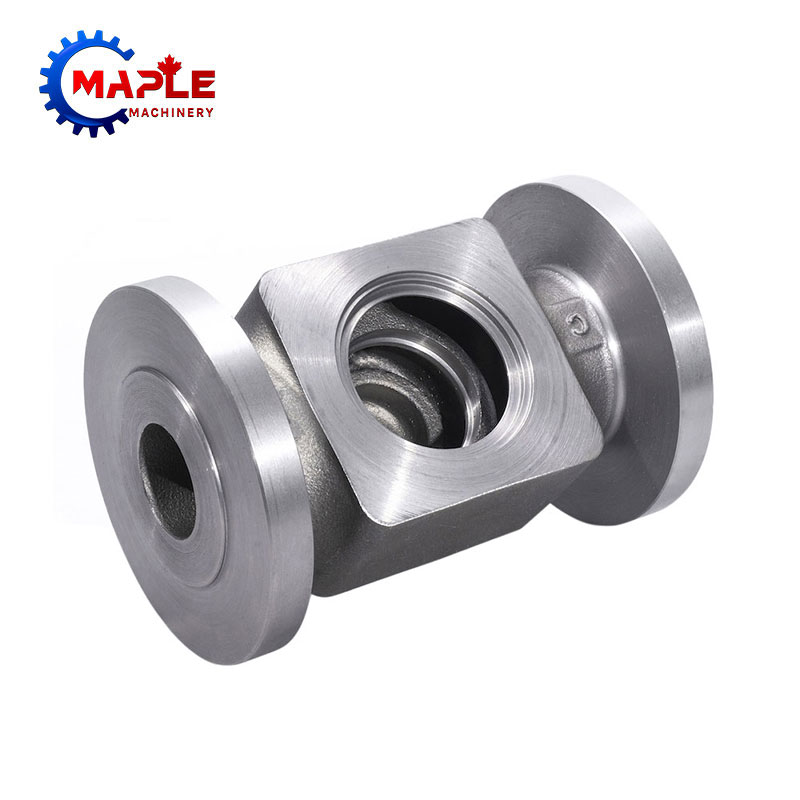

Ohišja ventilov iz litega železa Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

Deli za litine iz sivega železa za predelavo hrane

Deli za litine iz sivega litina našega podjetja za predelavo hrane uživajo velik ugled med končnimi uporabniki, ki izdelujejo različna strojna orodja in stroje za rezanje kovin. Širok nabor ulitkov se uporablja v splošnih strojih za predelavo hrane. Nudimo tudi opremo za jedro matrice. Ta oprema je v skladu z našo lastno tehnologijo ulivanja kovin, ki zagotavlja visoko kakovost notranjih in zunanjih površin ulitkov.Deli za jeklene litine v pesek za gradbene stroje

Naše strokovno znanje na različnih področjih se široko uporablja. Imamo raznoliko proizvodno tehnologijo v gradbenih strojih in zagotavljamo kakovostne dele za jeklene litine v pesek za gradbene stroje in storitve za stranke gradbenih strojev. Kupcem zagotavljati kakovostne izdelke in storitve, kupcem zagotavljati kakovostne izdelke in storitve.Industrija recikliranja litin iz nodularne litine

Maple machinery deluje na trgu že vrsto let in je zanesljiv partner domačim in tujim izvajalcem. Industrija recikliranja Liti deli iz nodularne litine, ki jih proizvajamo, se pogosto uporabljajo v industriji recikliranja. Naša prednost je celovita storitev - zagotavljamo izdelavo specializiranih ulitkov ter strojno in toplotno obdelavo, s čimer močno skrajšamo čas izvedbe naročila. Imamo lastno modelarno, kjer izdelujemo lesene in smolne modele. Imamo dobro opremljeno livarno in sodobno proizvodno linijo brez kalupov za steklenice.Deli za ulivanje jekla v naftni in plinski industriji

Maple je ISO certificiran livarski in predelovalni obrat z bogatimi izkušnjami na področju proizvodnje delov za ulivanje jekla v naftni in plinski industriji. Naši strokovnjaki za investicijsko litje vam bodo nudili vso pomoč, od odpravljanja težav pri načrtovanju do izbire prave zlitine za vaše delovno okolje.Liti deli iz nodularne litine za težko industrijo

Nahaja se v Ningboju na Kitajskem, blizu pristanišča, ima lastno proizvodno tovarno in inženirsko ekipo, ki je namenjena zagotavljanju rešitev strankam za delo s kakovostjo in najnovejšo tehnologijo. Služi vsemu svetu. Zahvaljujoč našemu strokovnemu znanju, našim sodobnim strojem in visokokakovostni proizvodni tehnologiji stopnja proizvodnje zagotavlja pravo količino visokokakovostnih litin iz nodularne litine za težko industrijo.Deli iz nodularnega litega železa

Maple machinery s svojim obsežnim tehničnim znanjem in visoko usposobljeno ekipo razvija prilagojene rešitve za dele iz nodularnega litega železa v skladu s potrebami naših strank. Dajanje prednosti zaupnosti, odgovornosti in trajnosti v odnosih z vsemi zainteresiranimi stranmi, ob upoštevanju srednjeročnih in dolgoročnih ciljev podjetja Valve. Tehnične zahteve, določene v dogovoru s stranko, zagotavljajo prilagojene storitve. Servisna ekipa si prizadeva za hiter odziv in neposredno preglednost od razvoja projekta do poprodaje. Zagotovite rešitve za ulivanje v skladu z zahtevami in specifikacijami kupcev.

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy