Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

Jeklene komponente za rafinerije plina in nafte Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

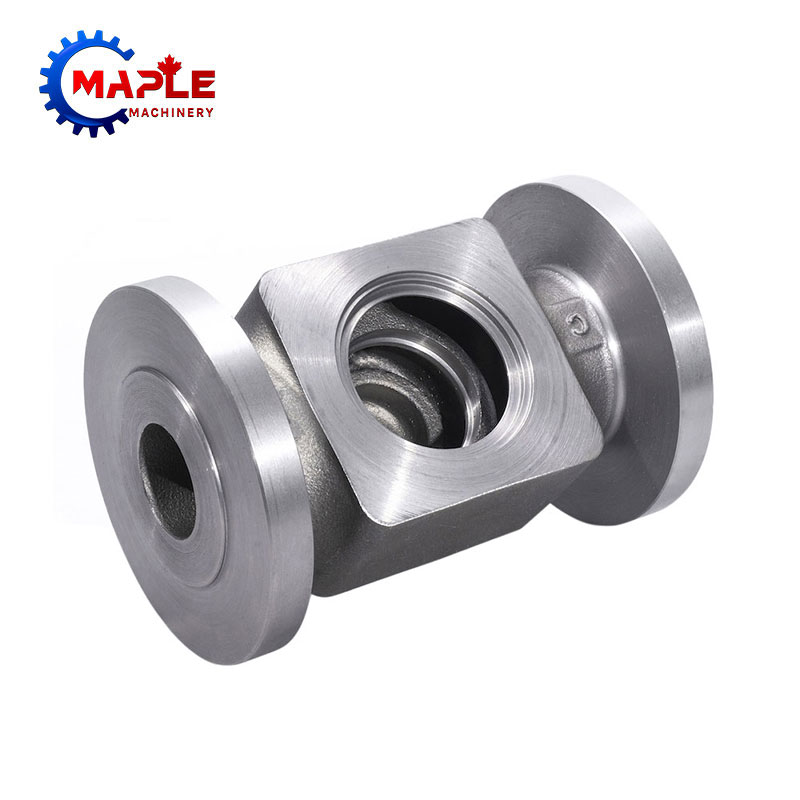

Deli za litje izgubljenega voska iz jekla hidravličnega sistema

Maple machinery vlaga v sodobno in sofisticirano opremo, da bi izpolnil vse zahteve kupcev za dele za litje iz izgubljenega voska iz jekla hidravličnega sistema v smislu zanesljivosti, ponovljivosti in prilagodljivosti. Maple machinery ima bogate izkušnje z ulivanjem po izgubljenem vosku in industrijskimi certifikati, ki se vsakič posodobijo in izboljšajo.Industrija recikliranja Deli za litje železa v pesek

Maple machinery je livarna visokokakovostnih ulitkov iz sive in nodularne litine za industrijo recikliranja. Podjetje je v ospredju svojih ciljev maksimiranja zadovoljstva strank in visoke kakovosti ter zagotavljanja visokokakovostnega peska za dele za litje železa v pesek za reciklažno industrijo za zagotavljanje bistvenih podpornih storitev, kot so proizvodnja kalupov in storitve skladiščenja, testiranje in vrednotenje kovin, izdelava prototipov, deli dodelava, predelava, premazovanje in toplotna obdelava.Odkovki jeklenih delov za mornarje

Kovanje jekla je glavna vrsta kovinskega kovanja tehnologija oblikovanja jekla, ki uporablja lokalno stiskalno silo. Odkovki so bili podvrženi pomembnim spremembam, kar je privedlo do učinkovitejših, hitrejših in dolgotrajnejših procesov. Dandanes se ladijski jekleni kovani deli običajno izdelujejo z električnimi, hidravličnimi ali kovaškimi stiskalnicami ali udarnimi orodji na stisnjen zrak. Vroče kovanje vključuje segrevanje obdelovanca na približno 75 % temperature taljenja.Deli za litine iz nodularne litine za naftno in plinsko industrijo

Smo vodilni proizvajalec in dobavitelj delov za litine iz nodularne litine za naftno in plinsko industrijo, vključno s pokrovi vodnjakov in požiralniki iz nodularne litine, inženirskimi deli in mehanskimi deli. V naši več kot 15-letni zgodovini sta nam naše tehnično strokovno znanje in vodstvo omogočila razviti nabor inovativnih izdelkov, ki našim strankam in izvajalcem prinašajo znatne dobičke.Deli za litje iz nerjavečega jekla za predelavo hrane

Strojni inženirji podjetja Maple za Food Process Machine delujejo kot razširitev vaše organizacije pri razvoju preciznega litja. Z vedno premislekom, ali bi lahko bile stvari »tehnično boljše, drugačne, cenejše in/ali enostavnejše«, dobimo najboljšo rešitev po konkurenčni ceni. Z veseljem delimo svoje znanje o tehnikah litja z vami, da oblikujemo najboljše dele za litje iz nerjavečega jekla za stroje za predelavo hrane.Deli za litje izgubljenega voska za jeklo za težko industrijo

Prek robustnega sistema vodenja kakovosti, brezkompromisnega upoštevanja uveljavljenih standardov, neusmiljene osredotočenosti na natančnost in nenehnega prizadevanja za izboljšave in zadovoljstvo strank – vse to so elementi, ki nam pomagajo pri zagotavljanju najkakovostnejših delov za ulivanje izgubljenega voska za jeklo za težko industrijo našim strankam po vsem svetu.

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy