Pokličite nas

+86-19858305627

Pišite nam

sales@maple-machinery.com

Jekleni ulitki za težke obremenitve za sektor nafte in plina Proizvajalci

Naša tovarna ponuja litje v pesku, zaprto kovanje, odprto kovanje itd. Ekstremni dizajn, kakovostne surovine, visoka zmogljivost in konkurenčna cena so tisto, kar želi vsaka stranka, in to vam lahko ponudimo tudi mi. Jemljemo visoko kakovost, razumno ceno in popolno storitev.

Vroči izdelki

Kmetijski stroji Jekleni deli za naložbeno ulivanje

Kmetijstvo je najstarejša panoga na svetu, zagotavlja človeku način preživetja. Agricultural Casting ima ogromen trg za ulivanje jekla za vlaganje in litje železa. Maple Machinery je od leta 2002 proizvajalec in dobavitelj jeklenih delov za ulivanje kmetijskih strojev. Naši glavni kupci v industriji kmetijskih strojev izdelujejo dele za ulivanje jekla za traktorje, kombajne, balirke, sejalnice, trosilnike, pluge, opremo za obdelavo tal in drugo kmetijsko mehanizacijo.Deli za jeklene litine v pesek za predelavo hrane

Maple Machinery je podjetje, specializirano za obdelavo kovin, litje kovin, CNC natančno obdelavo. Specializirani smo za proizvodnjo jeklenih delov za ulivanje v pesek za stroje za predelavo hrane po meri in imamo specializirane inženirje za podporo izvoznim storitvam. Naši inženirji dobro poznajo mednarodne ocene in standarde. Na izvoznem področju delujejo že skoraj deset let. Nudimo zanesljive in cenovno ugodne rešitve za kovinske izdelke. Lahko izkoristimo našo nizkocenovno strukturo na Kitajskem, da zagotovimo poceni in zanesljive končne izdelke po nižji ceni kot dobavitelji v skoraj vseh drugih državah. Naša ekipa izkušenih vodij projektov, inženirjev in strokovnjakov za zagotavljanje kakovosti vodi nabavne in proizvodne projekte kot kitajska zveza naših strank.Deli za litje iz nerjavečega jekla v težki industriji

Maple machinery je napreden proizvajalec livarskih delov iz nerjavečega jekla za težko industrijo na Kitajskem z zadovoljnimi strankami po vsem svetu in dobro uveljavljenim ugledom v livarski industriji. Ima skoraj 20 let izkušenj s proizvodnjo na področju nerjavečega jekla. Predvsem stroji Maple lahko ponudijo prefinjene izdelke za litje iz nerjavečega jekla.Deli za litine iz nodularne litine za naftno in plinsko industrijo

Smo vodilni proizvajalec in dobavitelj delov za litine iz nodularne litine za naftno in plinsko industrijo, vključno s pokrovi vodnjakov in požiralniki iz nodularne litine, inženirskimi deli in mehanskimi deli. V naši več kot 15-letni zgodovini sta nam naše tehnično strokovno znanje in vodstvo omogočila razviti nabor inovativnih izdelkov, ki našim strankam in izvajalcem prinašajo znatne dobičke.Deli za ulivanje jekla za gradbene stroje

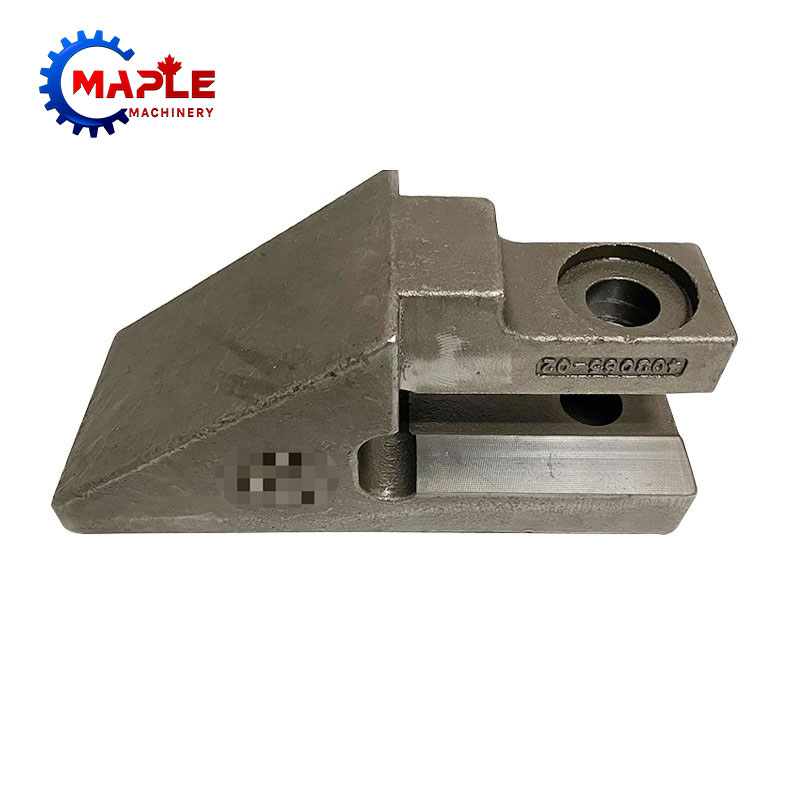

Pri Maple Machinery so kakovost, varnost in storitve naša bistvena konkurenčnost. Naša livarna ima napredno mehansko opremo in prilagodljivost, ki lahko izpolni vse vaše potrebe po delih za ulivanje jekla za gradbene stroje in vam pomaga izpolniti zahteve zahtevnih strank. Naša livarna je zavezana ohranjanju varnosti, čistoče in učinkovitosti. Z leti je Maple nenehno vlagal v najnaprednejšo opremo, s čimer je bil v ospredju industrije.Rudarska industrija Deli za naložbeno ulivanje jekla

Maple Machinery ima bogate izkušnje s proizvodnjo delov za naložbeno ulivanje jekla rudarske industrije. Kot proizvajalec na enem mestu z livarno in strojno delavnico v Ningbu. Že vrsto let smo specializirani za vlivanje jekla in končno obdelavo. Naši ulitki imajo konkurenčno cenovno prednost in pokrivajo večino evropskih in ameriških trgov. Veselimo se, da bomo postali vaš dolgoletni partner na Kitajskem.

Pošlji povpraševanje

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy